Detecting Errors in Metal 3-D Printing

About the Project

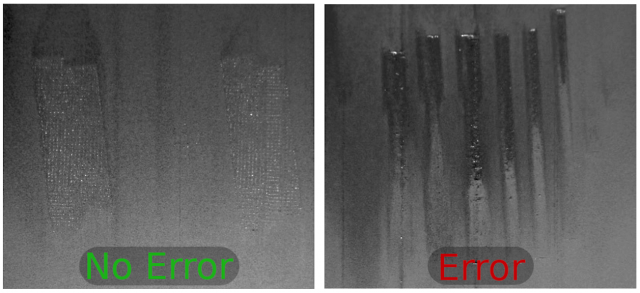

Powder bed fusion (PBF) metal 3-D printers produce parts by melting consecutive layers of metal dust. During a print, a built-in camera takes images of each layer, resulting in thousands of images per print. Over the course of a print, these images can catch errors such as leftover debris, warpage, and cracks. In the past, the images have not been utilized due to the large number of images per build. Currently, a practitioner needs to monitor the 3-D printer for the duration of a build to catch any errors. This is unrealistic as builds can take multiple hours. However, if practitioners do not monitor a build, then a fatal error can result in an unusable printed part. In our project, we attempt to identify the presence of errors in print images using Convolutional Neural Networks (CNNs). We compare performance across many model architectures and investigate the degree to which the CNN models overfit to the specific builds used in training. The long-term goal of this project is to produce an automated system which would accurately detect errors during the printing process, halting the machine when an error is found and notifying the practitioner.

Student Team

Mentors

- Dr. Xuan Wang, Professor at Cal Poly IME

- Michael Wu, Graduate student at Cal Poly IME